22 JULY 2022

Joint call for an accurate biogenic carbon accounting in the Product Environmental Footprint (PEF)

9 European associations call for a fairer method to account for the footprint of biogenic carbon and allocate it to the actors along the bioeconomy value chains.

Bio-based products are products wholly or partly derived from renewable materials of biological origin (i.e. from plants, crops, trees, algae and biological waste). These products are used in a wide range of applications, such as energy, textile, plastics, pharmaceuticals, hygiene, food and many more.

Ideally, bio-based products are circular by nature, since they are made of renewable resources, are designed to be re-used, re- and up-cycled several times, and at the end, for biodegradable ones, returned to nature through biodegradation or composting.

We need a fairer method to account for the footprint of biogenic carbon and allocate it to the actors along the bioeconomy value chains.

Biogenic carbon in the current PEF rules

In the currently proposed methodology of the Product Environmental Footprint rules addressing biogenic carbon, there is no recognized benefit granted to the producers of biomass-derived products, compared to fossil ones.

In a cradle-to-grave approach, the biogenic uptake and emissions of CO2 from disposal are balanced. Therefore, in such a cradle-to-grave approach, biomass derived products will not receive any CO2 burden when they are disposed of, while fossil products will receive a CO2 burden in case of incineration.

However, in a cradle-to-gate life-cycle analysis using PEF methodology, biomass-derived products will not receive any credit for the fact that CO2 was removed from the atmosphere during photosynthesis and plant growth. Whereas in LCA (ISO 14067, EN 15804 and other LCA standards) biogenic CO2 uptake in biomass-derived products shall be addressed.

When the use of the product cannot be singled out - like platform chemicals which are used for a range of different other products or intermediates -, the manufacturers need to supply a cradle-to-gate LCA. Accordingly, there will be no CO2 credit for bio-based raw materials calculated at the gate of the product. It will look like there is hardly any benefit from producing biomass-derived products if any at all, compared to fossil based.

The same “accounting” problem appears when biomass feedstock is blended with fossil feedstock, like in mass balance scenarios. There will hardly be any difference in greenhouse gas footprints as long as a cradle-to-gate assessment is used for life-cycle inventories and for full LCA where other forms of end-of life approaches than incineration are applied. Additionally with the current approach, the use of the products in long-lasting applications, investment goods and others are not considered as an actual removal of biogenic CO2.

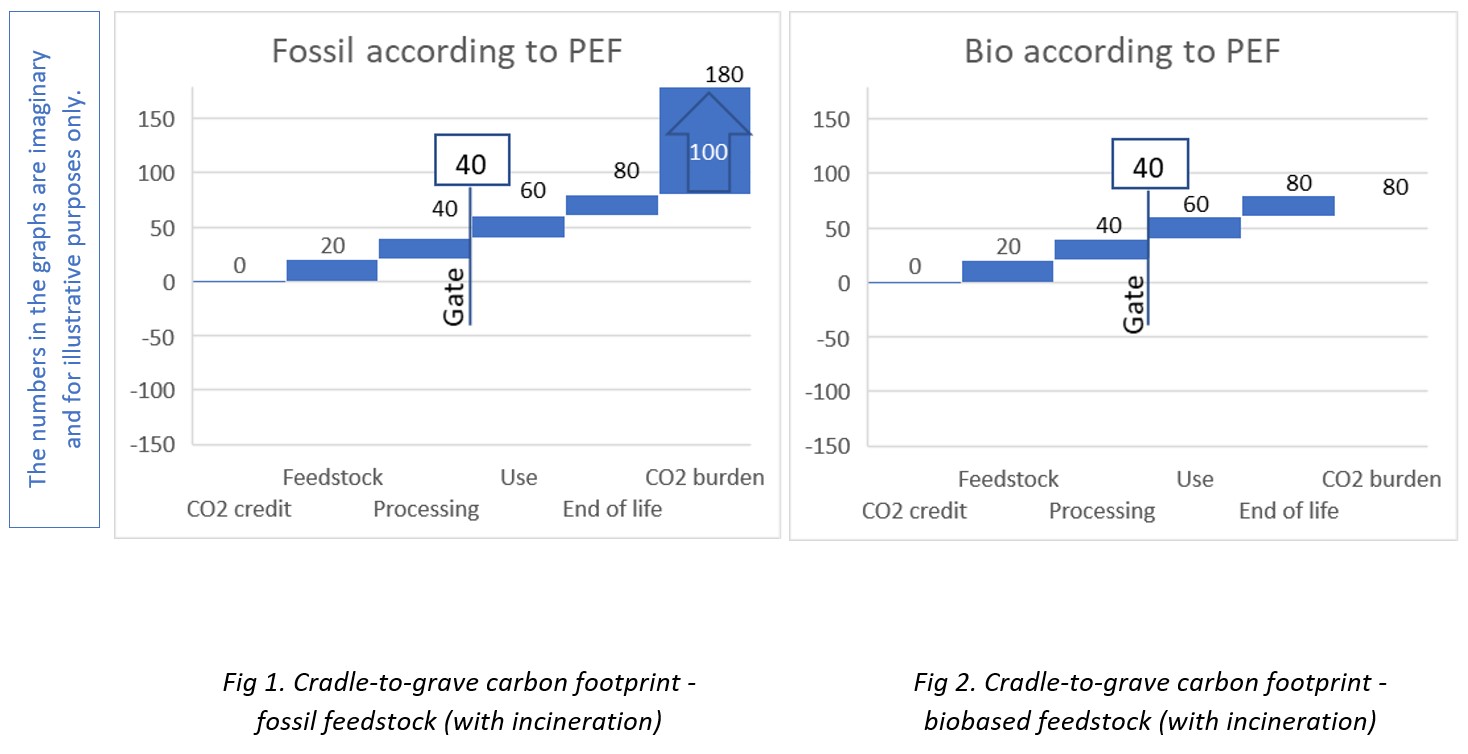

The figures (fig. 1 and 2) below illustrate this method used for an imaginary product made of both fossil- (grey) and bio-based (green) feedstock. For simplicity, we assume exactly the same CO2 footprint in production and logistics for these two feedstocks, as well as the same manufacturing processes and the same final uses. The only difference is in the CO2 emissions at end of life, where bio-based feedstock emissions are zero and fossil-based ones are substantial (= 100 in this scale). We easily see that there is no difference for cradle-to-gate LCA or for everlasting or recycled products that never will release CO2. This is counter-intuitive since we all know that CO2 was fixed during growth of the biomass and has not yet been released again until end of life.

Our proposal for biogenic carbon in “fairer” PEF supporting the European Green Deal

In our views, the current PEF methodology is not incentivizing the use of biogenic carbon. A much more meaningful way, applied in LCA and environmental footprint which is not in use in PEF today would be based on giving CO2 removals credits to biomass when produced AND giving CO2 penalty to all CO2 (bio-based and fossil) when it is actually released back to the atmosphere. In this case, the emissions and removals are shown alongside the time periods that are in the scope of the calculations. With this approach, the data can be shown in a transparent and meaningful way. In addition, this procedure follows the standard ISO 14067 which is the commonly applied standard. Furthermore, this will be much more in line with people’s perception and much easier to communicate. It shows the positive contributions of materials to the reduction of GHG emissions on the level of purchasing decisions and helps to promote the marketing of products with overall lower carbon footprints. It also allows for informed discussions on the different stages of the life cycle.

With this proposed approach, all released CO2 at end of life is counted as emissions regardless whether biogenic or fossil-based. Thereby, there is no further need to keep track of the origin of the carbon in the product and one avoids any double counting of CO2 credits, hence reducing any error. Even incineration of biomass, like energy production from pellets, will have to count their CO2 emissions. This will thus promote also the recycling of partly and fully bio-based products, Carbon capture and utilization (CCU), Carbon capture and storage (CCS) and long-term storage of carbon, which is in line with the objectives of the Sustainable Carbon Cycles initiative (COM(2021)800 final).

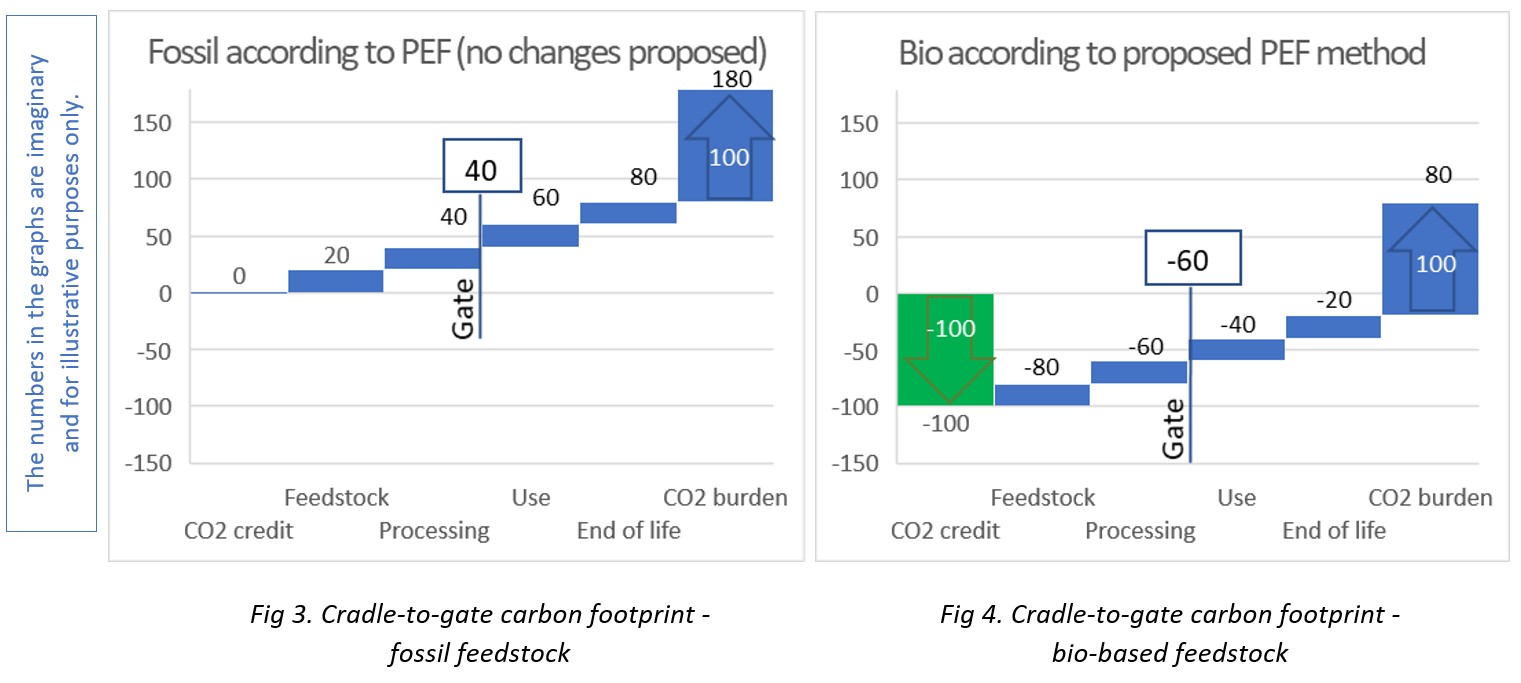

The figures 3 and 4 illustrate such an alternative and more meaningful accounting method, based on the same imaginary product produced from fossil- (grey) and bio-based (green) feedstock. Again, for simplicity, we anticipate exactly same CO2 footprint in production and logistics of these two feedstocks, as well as the exact same manufacturing processes and the same final uses. The only difference is in the CO2 emission at the cradle, where bio-based is negative (due to uptake of CO2) and fossil based is zero. With this method there is the same total carbon footprint at end of life as with method 1, but the difference also shows up at any stage during processing and use.

Our recommendation

Collectively, we are convinced that the use of the proposed alternative methodology to account for the carbon impact of biomass-derived products within the Product Environmental Footprint will be more intuitive and transparent, is ISO and CEN compliant, and will show the actual difference in CO2 footprint between biomass-derived and fossil products at any stage of the life cycle, irrespective of the selected system boundaries and end-of-life scenarios linked to the functional unit of an LCA. In addition, it will avoid the challenges of double counting of CO2 credits, since all “end-of-life” CO2 emissions will have to be counted as contributing to climate change, whether biogenic or fossil-based. It will support the use of bio-based materials, product recycling, long term storage of carbon, CCU and CCS, in line with the Green Deal objectives. This will enable customers and consumers to make an informed purchasing decision, based on the demonstrated and transparent climate benefits of bio-based solutions.

We recommend adapting the current Product Environmental Footprint accordingly, especially in the context of the Sustainable Products and the Green Claims and Consumer Empowerment initiatives.

Download the position in pdf